BRAKE HOSES

BRAKE HOSES

|

||

|

||

|

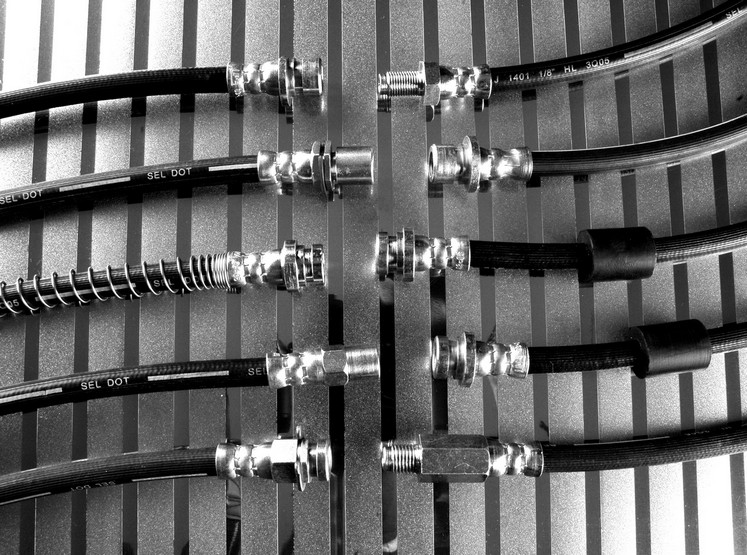

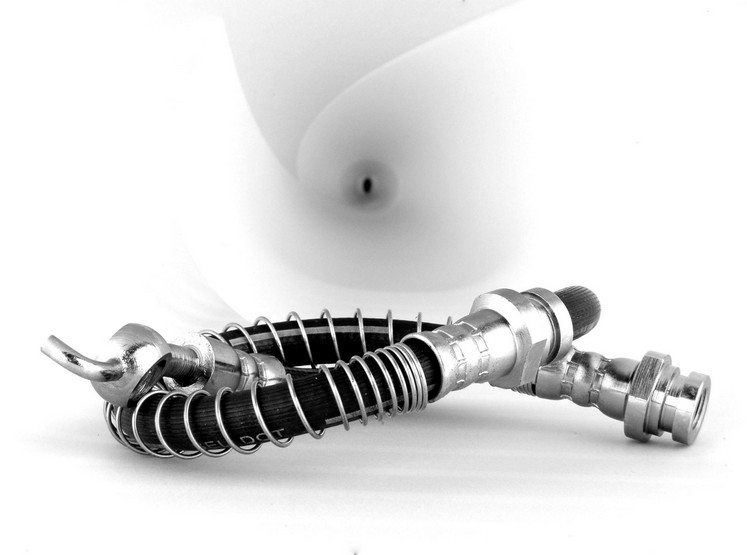

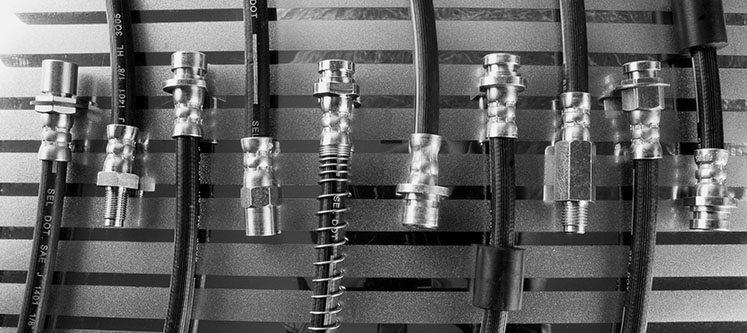

It is easy to forget how important the brake hoses are among the many parts that bring a braking system. Simply put, the Brake Hose is a very critical piece of safety in all vehicles. Whenever brakes are used, brake hoses operating under overvoltage must be checked regularly because any error can cause brake fluid loss. This means a drop in pressure and can cause severe braking failures. The brake hoses transmit the pressure brake hydraulic fluid, which is sent from the brake center through the brake pipes under pressure, to the wheel brake system. The hydraulic connection must be able to work flexibly as it transmits to the moving wheels and must be durable since there is direct contact with the outside. The brake hoses are connected to the brake pipes and to the brake cylinder on the wheel by connecting fittings. Rubber and steel mesh are used together to increase the strength of the brake hoses. The only way to check if a Brake Hose is operating correctly is to perform a visual inspection. If there are visible cracks or leaks, this may be an indication that the whole brake network is damaged, because all brake parts wear off at similar rates. Lima Hortum Sanayi recommends replacing Brake Hoses every five years or 50,000 km to avoid compromising safety at any point. The only way to ensure our hoses' performance on the road under high pressure is to test them under extreme conditions. This is always the work we do over and over again. Our test procedures have the following features:

|

||

|

||

Other Pictures |